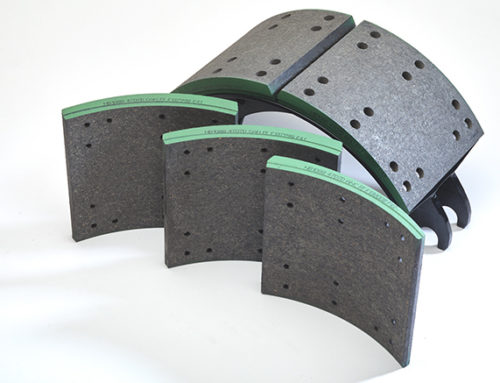

OAK CREEK, Wisc. – March 21, 2017: NeoBrake Systems, Inc., an early North American heavy-duty brake remanufacturer and formulator of world-class asbestos-free brake linings and pads, announced today a major breakthrough in S-cam foundation brake performance with the introduction of Matrix NeoCast™, a revolutionary new lightweight cast iron 4707Q brake shoe.

Matrix NeoCast 4707Q is the first lightweight cast iron shoe of its kind, combining the traditional advantages of cast iron shoes – lasting rigidity, superior heat dissipation, sustained maximum torque, and optimal lining-to-drum contact – with an advanced, high-carbon ductile cast iron that weighs significantly less than cast shoes of old.

“The future may be air disc brakes, but the roadways are filled with trucks and trailers still using drum brakes to stop them,” stated Rick Ballew, NeoBrake president and CEO. “We know the beating pressed-steel cores take after each relining, so we developed a shoe that could resist all that and deliver maximum braking power at every stop.”

According to Ballew, safety is the driving force behind his Milwaukee-area-based reman brake shop, which he opened in 1988. Through the years, he’s seen the various changes in the industry and has adapted his operation accordingly. But the one mistake he always believed the industry made was moving away from cast iron. So when he had this idea, he knew the only obstacle standing in his way was weight. An obstacle he quickly overcame once he learned of this next-generation casting technique.

“I travel the world to find the best suppliers and that quality edge to incorporate in my products,” shared Ballew. “When I stumbled upon this high-carbon, ductile cast iron, I knew we had the green light to bring back the only true material for brake shoes and boost drum brake stopping power.”

The Matrix NeoCast 4707Q brake shoe weighs within ounces of its pressed-steel counterparts and promises to boost braking power from the moment it is installed – never letting up until the day it is retired. How long the this lightweight cast iron 4707Q shoe will last depends on multiple factors, which include the experience level of the driver and application, but Ballew guarantees it will last longer than any pressed-steel core. In fact, he doesn’t shy away from making the same claim about linings, drums, and air brake system components.

“Whatever service life you’re getting out of your linings and wheel-end components now, it will be longer with Matrix NeoCast shoes,” said Ballew. “One of our drivers reported it taking half the air pressure to engage his brakes. He knew they’d help him stop better, but was equally impressed with the amount of stress it took off his air brake system.”

The Ultimate 4707Q Brake Shoe.

Matrix NeoCast’s rigid, one-piece construction eliminates table flex, web stretch, and broken welds, which are common signs of deteriorating pressed-steel shoes. This leads to diminished torque, as well as uneven lining wear and, ultimately, premature lining replacement. Yet, the standard practice is to coin the shoe true every time it comes in for relining, then send it back out. Which, told by Ballew, is the heart of the problem.

“Pressed-steel cores get softer and softer until they wear too thin to use, if their welds haven’t broken before then,” explained Ballew. “That won’t happen with our Matrix NeoCast shoe – that’s the beauty of cast iron. In fact, we fully expect this shoe to resist rust or rust-jacking for at least the average life-cycle of a new truck or trailer based on its cast iron composition and properties.”

Unit pricing is yet to be finalized for this breakthrough cast iron 4707Q shoe, but Ballew has begun negotiating contracts with existing customers, including work truck, tractor and trailer OEMs, as well as fleet operators, offering attractive pricing programs for early adaptors. Per unit, the Matrix NeoCast shoe will run higher than pressed-steel shoes, but Ballew is quick to emphasize the cost savings and improved safety aspects of his product over its life cycle.

“Pressed-steel cores were originally developed as one-use products,” shared Ballew. “Ever since there’s been a domino effect on safety and maintenance costs, and this shoe gets the industry back to where it started without the added weight of old cast iron. Which makes even more sense now, with stopping distances being a top priority, because Matrix NeoCast will improve the stopping power of trucks and trailers unaffected by stopping distance mandates.”

Today, The Lightweight Cast Iron 4707Q. Tomorrow…

Matrix NeoCast shoes are currently available for all 4707Q applications and can be purchased from NeoBrake or through an authorized NeoBrake dealer. Additional sizes are currently in development and will be available once completed.

For more information on the industry’s first lightweight cast iron 4707Q brake shoe, contact President/CEO Rick Ballew at 414-764-4211.